Applications

Engineering Notes

![]()

Failure Mode Analysis (FMA) Report on ESD Damaged White

LEDs

Background:

On April 2003, one of our customers

reported that they had experienced over 100 failures in their recently

received first batch of 100K white LED lamps. The customer reported that the

white LED lamps had instantaneously flashed ON after being connected

together during product assembly and then did not work anymore

thereafter. Immediately it was suspected that Electro Static Discharge (ESD)

damage was causing such failures. As measures were put in place in

their production facility to reduce all possible sources of ESD damage

(proper grounding of all equipment and personnel), a dramatic drop in

the failure rate/quantity while running production was experienced

(from over 166 pieces per 18,000 to 1 per 900).

Brite-LED received 166 �bad� LEDs,

which were sent by the customer for test and evaluation to confirm and

determine the actual cause(s) of their failure and thus the reason for

this report.

Evaluation

and Testing:

1.

Each of the 166 LEDs were tested individually with an HP Lab

Bench DC Power supply, by supplying a varying current. All of the LEDs

came ON. However, this happened at different forward current (IF)

levels.

2.

A few came on at or around just 1mA, a large group came ON

at around 15mA, other group came ON only after the applied forward

current reached 50mA, and a few came ON after the applied forward

current reached 150mA.

3.

On the LEDs that required the very high currents to turn ON,

the forward voltage increased very slowly at first as the applied

forward current was increased, but once they reached the turn ON

point, the current suddenly dropped and the voltage settled to the

corresponding expected VF levels.

4.

Once all the LEDs that required very high currents to turn

ON got �Started�, they came ON in subsequent trials at much lower

currents (8mA to 15mA). As if they got �semi-fixed�.

5.

A randomly picked group of 30 LEDs was inspected under a

microscope to look for any evidence of bond wire or die damage. None

was found. The wire bonds were intact. This finding revealed good

quality LED packaging given that the customer had bent outwardly the

leads of all LEDs extremely close (<1mm)

to the lower side of the epoxy lens, which could have caused

wire bond breakage.

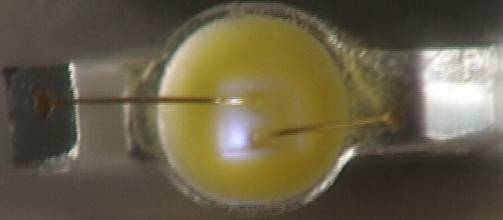

Fig 1. Some LEDs come ON at IF=1mA

6.

A forward current was slowly applied to

some LEDs while the die was closely observed to find the turn ON point

and how the die behaved. It was found that in the LEDs with a high

current turn ON point, only half or a quarter of the die would come ON

at first. (See attached picture sequence below).

Close-up Pictures of LED that came ON at 1mA

Fig 2. LED is OFF (No current applied) Fig 3. LED just starts to turn ON (IF≈0.7mA; VF=2.47V)

Close-up

picture of a more severely damaged LED that comes ON at 29mA

Fig 4. Only a corner of the LED die comes ON at first. (IF=29mA; VF=2.42V).

8.

Another LED, similar to the one in figure 4, did not

initially come ON until a 170mA forward current was applied (@ VF=3.48V),

then suddenly the VF dropped to 2.71V and the forward

current dropped to 16mA. After that, the LED came ON at 15mA on

subsequent trials.

Conclusions

of Findings:

1.

As initially suspected, Electro Static Discharge (ESD)

caused the damage to the LEDs.

2.

This conclusion is based on the all of the compounded clear

evidence and behavior of the LEDs.

3.

ESD damage can range from catastrophic failure to various

degrees of non-so-evident damage.

4.

ESD damage to an electronic device, such as an LED, may lead

to intermittent behavior or premature device failure.

5.

ESD damaged devices can appear dim, dead, shorted, or with

low VF or VR All of the devices

tested show one or all of these symptoms

6.

Light

Emitting Diodes are static sensitive devices. InGaN on Sapphire die

(used in these white LEDs) is generally considered and thus rated as

an ESD Class 1 device (can survive 20V bias with Machine Model

Testing, and 130V from Human Body Model Testing). Static charges of

30K volts are not uncommon and can be generated quite easily.

7.

ESD caused internal damage in the LED die by creating shunt

current paths, which was evidenced by the low VF and high IF.

8.

When the applied Forward current was high enough, new paths

were created, thus �fixing� the LED. However, although this might

be considered a way of �fixing� the LED, in reality the LED is not

completely �healed�. It�s

efficiency and life is permanently affected, both most likely

decreasing.

Recommendations:

An ESD Safety

and Control Program must be put effectively in place. Generally such

program includes provisions for Charge Protection; Grounding;

Shielding; Neutralization; Use of Anti-Static Materials, Work Stations

and other Materials and Equipment, and last but most important,

Education and Training.

The primary

method of ESD Control is to properly ground (or bring to the same

potential) all conductors that come in contact or are in near

proximity to the electrostatic sensitive devices (the LEDs in this

case). These conductors include humans, tools, mats, other electronic

devices, boards, connectors, packaging, etc. ESD sensitive devices

should always be placed inside enclosed antistatic shielding bags and

containers during all routine handling such as inventory storage,

transportation and WIP.

An evidence

of the impact of all of the above listed measures is the dramatic

decrease in the failure rate and quantity of LEDs after ESD prevention

and control measures were put in place and/or increased in the

customer�s production line area.

![]()

| HOME | PRODUCTS | ABOUT US | SALES | CONTACT US |TECHNICAL INFO |

copyright (c) 2002-2005 brite-led.com all rights reserved